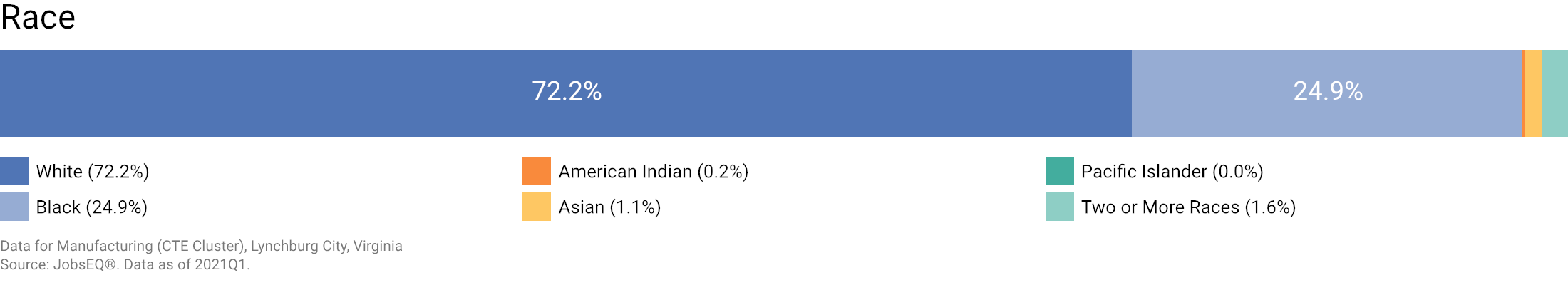

As the home of companies like U.S. Pipe, L&R Precision Tooling and Banker Steel, the City of Lynchburg has a storied legacy and sustainable future for Metals and Machinery Manufacturing. While other areas across the country struggle to preserve a viable production sector, Lynchburg has maintained its competitive advantage. Not to mention, the community has built a reputation for combining traditional manufacturing with advanced capabilities, as demonstrated by its growing expertise in the development of Conveyor Systems and Moving Equipment, led by the likes of Automated Conveyor Systems, Inc., and Alliance Industrial Corporation. As the analysis below indicates, the City of Lynchburg has a skilled talent base from which to draw expertise. With over 12% of all LYH jobs in this cluster, the City and its private and public partners must continue to expand this cluster by developing an ongoing skills pipeline.